PPS

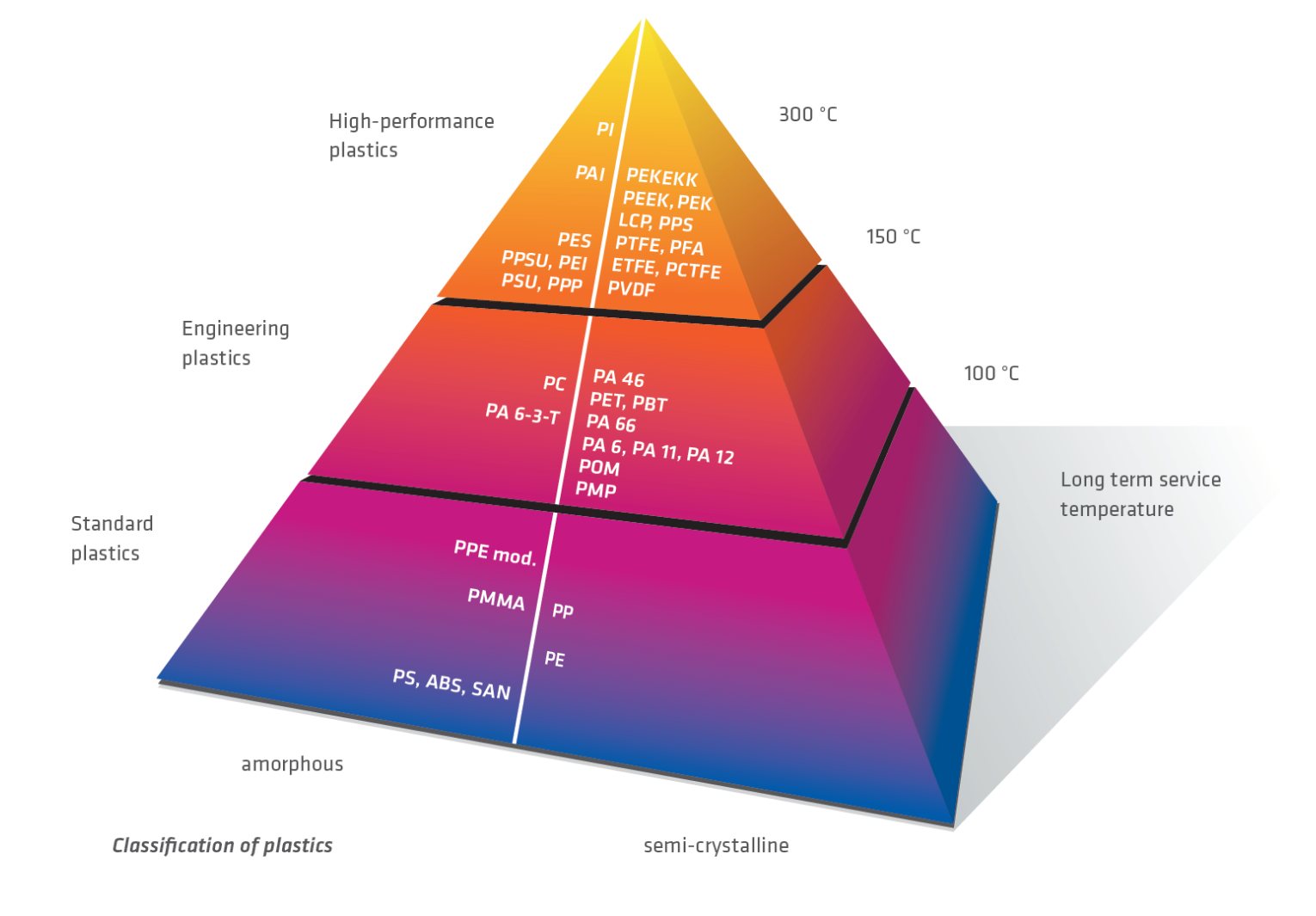

PolyPhenylene Sulfide (PPS) material series is a semi-crystalline engineering thermoplastic that offers the broadest resistance to chemicals of any high-performance melt fluoropolymer resin. There are no current solvents that affect PPS under 200°C, and it is inert to steam, strong bases, fuels, and acids. PPS is ideal for precise tolerance machined components because it has minimal water absorption, has a very low coefficient of linear thermal expansion, and is stress-relieving manufactured.

Main features

Outstanding chemical resistance

Resistant to hot water and steam

Strong Material Performs at elevated temperatures

Good dimensional stability

High dielectric strength